Battery-powered electric vehicles (BEVs or EVs) are the new revolution in the transport domain that accounts for nearly 16 % of global emissions. It is eco-friendly and requires less maintenance and operating costs.

Battery-powered electric vehicles (BEVs or EVs) are the new revolution in the transport domain that accounts for nearly 16 % of global emissions. It is eco-friendly and requires less maintenance and operating costs.

Electric vehicle (EV) sales in India reached a record 1.95 million units in 2024, an over 27% growth year-over-year against the 1.53 million units sold in 2023.

EVs accounted for 3.6% of overall automobile sales, according to data released by the Ministry of Road Transport and Highways through its Vahan Dashboard.

The major problem in EV adoption is range anxiety, this is because of immature battery technologies and a lack of charging infrastructures.

By the end of 2022, India had 2,700 charging stations and may require 20.5 lakhs of charging stations by 2030.

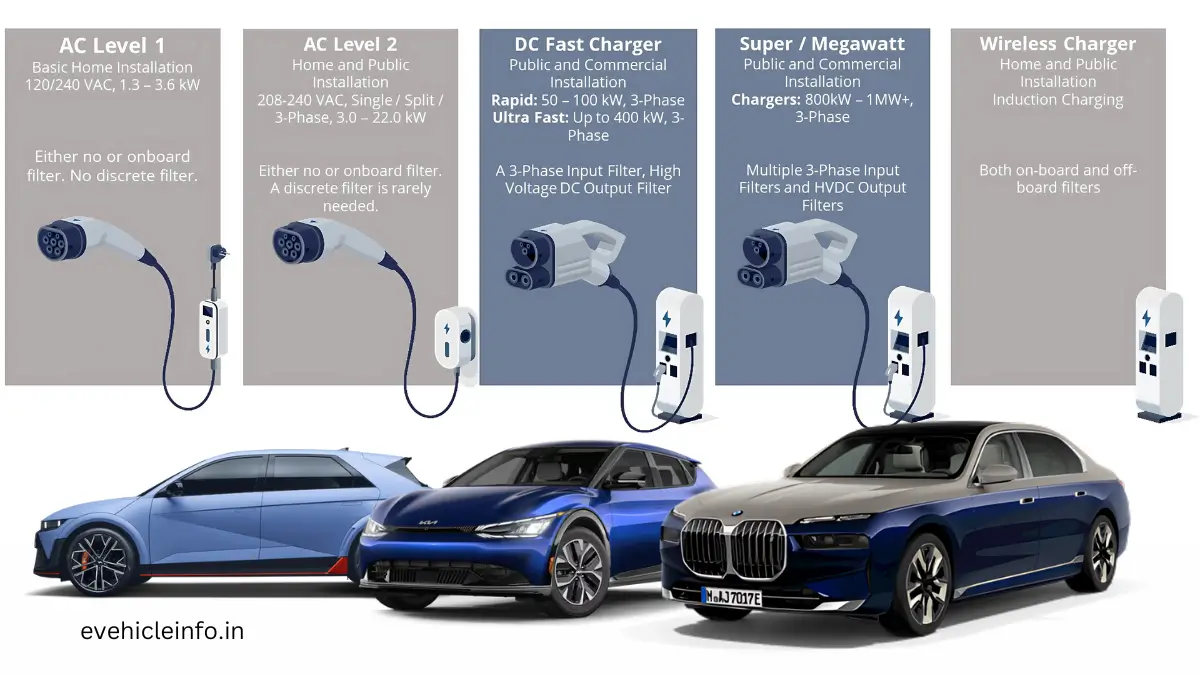

There are different methods and types of charging available for electric vehicles.

Conductive Charging

It is the most widely used method and is comparatively less expensive.

Level 1 Charging

It uses AC power to charge the electric vehicles and the charger is plugged in the same way as other electronic equipment (like mobile chargers, and TV).

It uses AC power to charge the electric vehicles and the charger is plugged in the same way as other electronic equipment (like mobile chargers, and TV).

Level 1 charging is very slow. It primarily covers home charging. It uses single-phase electric energy.

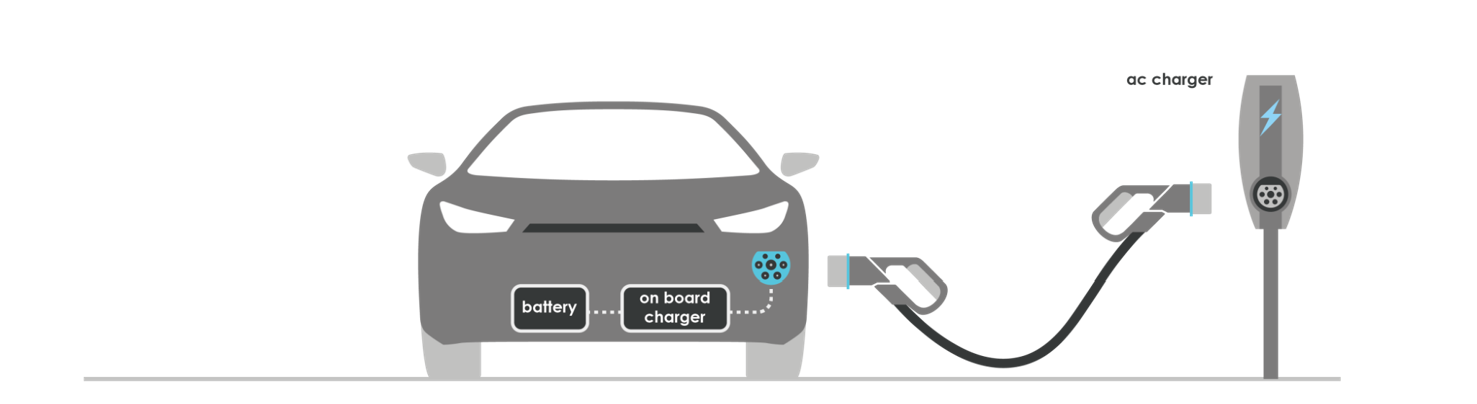

It is an onboard charger means a power converter unit is installed on the vehicle to convert the AC power to DC to charge the battery.

Level 2 Charging

It is the most common public EV charging. It can be a single or three-phase level.

It is the most common public EV charging. It can be a single or three-phase level.

In this method, the vehicle is connected to an onboard charger which is capable of accepting energy from alternating current EVSE.

Level 3 Charging

Level 3 uses AC or DC power to charge electric vehicles. It is used by charging stations.

Level 3 charging is the fastest type of charging available and can recharge an EV at a rate of 3 to 20 miles of range per minute.

It requires high voltage and power, so it is not installed at home and it generates more stress (electrical loads) on the power grid. It is commercially installed across highways, hotels, and shopping complexes.

It is available only as an off‐board charger because the charging power is high and may exceed 100 kW. Its installation and operating costs are high.

A brief comparison of the above techniques-

| Para-

meters |

Level 1 | Level 2 | Level 3 (AC) | Level 3 (DC) |

| Voltage (V) | 240 | 380-400 | 200-1000 | 200-1000 |

| Power (kW) | <=3.5 kW | <=22 kW | 4.3 to 22 kW | Up to 400 kW |

| Type of Vehicle | 4w ,3w,2w | 4w ,3w,2w | 4w | 4w |

| Type of compatible charger | Type 1, Bharat AC-001 | Type 1, Type2 GB/T, Bharat AC-001 | Type 2 | Type 2, CHAdeMO, CCS1, CCS2 |

Types of Compatible Charger(connector) –

AC Connector (slow charging)

| Type 1 or J1772 | Type 2 or Mennekes |

| It has 5 pins and is a Standard US Connector. | It has 7 pins, the last two pins are for communication and it is a Standard EU connector. |

| It can carry single-phase current only. | It can carry 3 3-phase currents also. And can be used for DC charging also. |

| The typical power ratings it handles are 3.7 kW and 7 kW. | Handles 3.7 kW, 7.4 kW, and 22 kW. |

| It has no locking mechanism. | It has an inbuilt locking mechanism. |

DC Connector (Fast Charging, 10-400 kW)

| GB/T Connector | CHAdeMO Connector | CCS1 and CCS2 Connector |

| Mainly used in China and transfers 250 kW of power. | Developed by Japan and transferred up to 400 kW. | Used in North America and the EU and transfers up to 350 kW. |

| CAN Protocol is utilized to make communication between the electric car and the charging system. | CAN Protocol is used. | It communicates between an electric car and the charging system via a PLC (Power Line Communication) |

TESLA has created its proprietary plug-in North America for charging its electric vehicles.

TESLA doesn’t have a separate connector design for AC and DC charging.

Battery Swapping Stations for instant charging

It is another way of charging the battery a discharged battery.

In this, a discharged battery is exchanged with a charged battery at a battery-swappable station, and the charge(money) is paid by the customer.

This process is like the filling of an LPG cylinder where an empty cylinder is given by the customer and the filled cylinder is given by the vendor.

It can be very useful for commercial EVs (rickshaws, taxis) where the battery can be charged (by exchanging) within a few minutes. This saves their time.

Battery Swapping can be easy for light vehicles as the weight of the battery is less.

Read More:

- Largest Lithium Reserves Found in Rajasthan and Jammu & Kashmir

- Comparison of Lithium Battery Cell Types, Sizes and Difference Form Factors

- Top EV Courses and EV Training Providers in India

However, robots (automated machines) are for heavier vehicles to exchange their batteries.

A brief note of its advantages and disadvantages-

| Advantages | Disadvantages |

| It saves time for EV users in charge. | Difficult for heavy vehicles to swap batteries. |

| Sometimes the battery is rented by a third party and is charged per swap so it reduces the EV cost for the customer. | Installing a battery swapping station is very expensive, maybe ten times more expensive than a fast charging station. |

| A charged battery can be used to feed power to the grid when the load on the grid is more. So V2G concept can be implemented. | Battery Standardization (weight, dimension) is not fixed. Greater number of batteries is needed to power the same number of EVs |

Notable Battery Swapping Service Providers in India

- Sun Mobility– Provides swapping service for 3W and e-buses

- ChargeUp– Aims to install 10,000 swapping stations

- Lithion Power– Provides swapping service for 2W and 3W.

- Charge+Zone- Only provides swapping serving for 3W

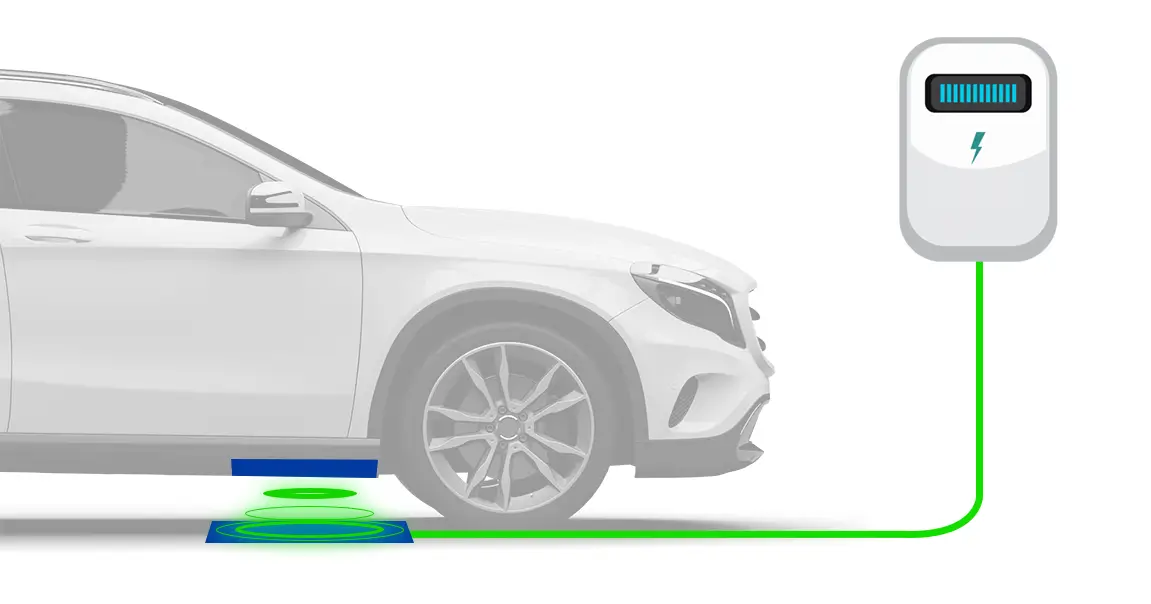

Wireless EV Charging

This method is still in the research & development stage. In this method, the electric vehicle battery is charged without the use of a charging chord just by parking (placing) the vehicle at a predetermined location.

It has two main parts one is called the transmitter (ground assembly) located underneath the road surface and the other one is the receiver (vehicle assembly) built into the vehicle body.

The power is transferred through electromagnetic flux from transmitter to receiver.

Wireless charging for EVs is categorized into stationary, semi-dynamic, and dynamic charging systems.

Stationary Wireless charging is similar to a plug-in charger where the EV is parked at a charging pad.

Semi-dynamic systems can be installed at bus stops, taxi stops, and traffic lights to provide short-term charging in a dynamic environment.

Dynamic wireless power transfer systems charge the battery when vehicles are on moving on the road.

Dynamic Wireless Charging gives unlimited range to EVs and no fear of range anxiety for drivers.

It is estimated that most wireless charging devices will operate at approximately 92%, ±2% efficiency while wired charging has 96%, ±2% efficiency.

Here is a brief table for Challenges and Opportunities of Wireless Charging

| Opportunities | Challenges |

| Unlimited Range with a lower capacity of the battery | Expensive infrastructure & efficiency yet less than Wired Charging |

| No physical contact is required, easy to use | Misalignment tolerance of the charging pad is a problem |

| EV cost is less as the lesser battery capacity is required | Universal standards for charging pads are not defined |